Part One of this series established that it’s important to calculate the entire cost of a shipment rather than the material (physical) cost of packaging alone. We, Protek Pharma Worldwide, chose to review the Total Landed Cost (TLC) concept to get the conversation flowing and get the minds of our industry whirring.

In Part Two we will dive into the details of how TLC really affects your business’ bottom line and will demonstrate how this can be explained in an equation (don’t worry you won’t need to do any maths!).

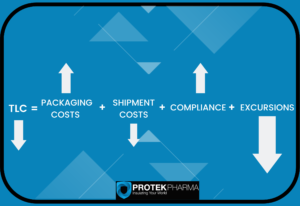

So let’s not beat around the bush, here is the equation:

Figure 1

Now this may look a bit complicated, however each step in Figure 1 is controllable and dependent on each other. Changing one element in the equation can cause a significant change in the outcome for your supply chain costs. For us at PPW, packaging is clearly our physical part of the equation. However, our team’s expertise covers all elements in the process in order to help customers reach a happy place where risk and expenditure is balanced.

Take a look at the below example and following explanation of the scenario, which should make this all even clearer:

Figure 2

In this example (Figure 2), the packaging solution for the shipment has been changed and the arrows show the effect this has had when a more holistic view has been taken.

In Figure 2, we can see that a more robust, reusable packaging solution has been chosen, which is now costing more per unit for the higher spec than the previous (lower quality) option. However, this now means that overall shipment costs have actually been driven down as the higher specification solution has resulted in a smaller (in size) overall parcel unit that’s easier to handle and more efficient to store – excellent! Finally, as the shipment now has an appropriate solution for this batch of pharmaceutical products, the overall excursions have fallen significantly, resulting in the Total Landed Cost being reduced.

By taking a more holistic view of the supply chain and assessing which solution is best-suited each shipment, your company can be in a much better position. All departments involved can be happy with the result.

Now we know today’s example is fictitious, but here at Protek Pharma Worldwide we encounter this scenario when reviewing solutions with companies on a regular basis. We will publish a real-life example in the coming weeks.

We understand if it can’t wait until then, so in the meantime you can head to our contact us page and we’ll be happy to help.